Sheet Cleaners

Customized sheet cleaning solutions that remove surface contamination and transfer it to an adhesive roll for disposal—an efficient solution to meet the most rigorous manufacturing environments, standards or needs.

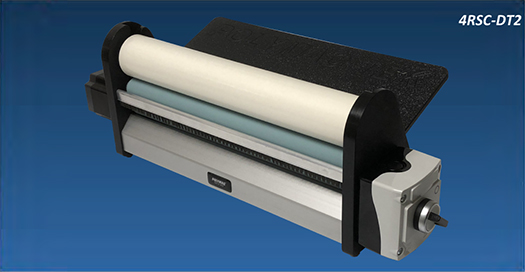

Two-Sided, Desktop Sheet Cleaner

This system offers big sheet cleaning capability in a small package.

More Details Connect With a Rep

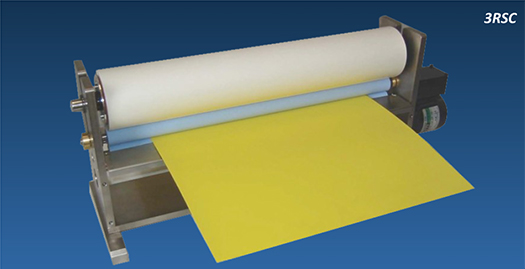

Two-Sided, Three-Roll Sheet Cleaner

This system offers customized sheet cleaning meet unique needs.

More Details Connect With a Rep

Two-Sided, Narrow-Sheet Cleaner with Pneumatics

This system offers customized sheet cleaning to meet unique needs.

More Details Connect With a Rep

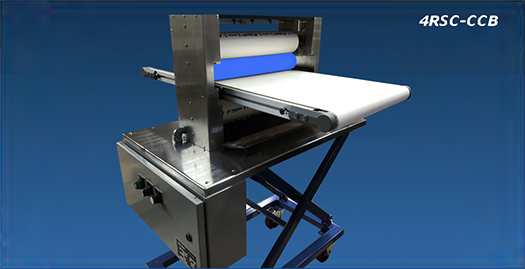

Two-Sided Sheet Cleaner with Cleaning Conveyor Belt

This system with contact cleaning belt offers customized sheet cleaning to meet unique needs.

More Details Connect With a Rep

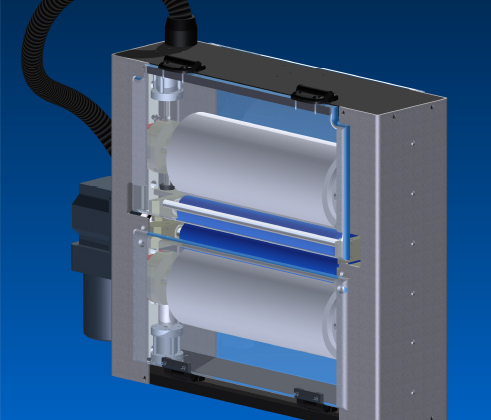

Two-Sided, Double-Nip Sheet Cleaner with Roll Separation Pneumatics

This system offers customized sheet cleaning to meet unique needs.

More Details Connect With a Rep

Frequently Asked Questions

In order to clean sheets effectively they cannot be shingled or overlapping. A sheet cleaner needs to be located in a place where the contact cleaning rolls have full contact across the full length of the sheet. Ideally this location is prior to the sheeting point where the substrate is in web form.

This depends on the process. If a sheet is going directly into a follow on operation like printing or coating, cleaning the bottom side may not be necessary. However, if the sheets are being stacked, contamination from the bottom of the sheet can deposit on the top of the sheet below it. In most cases cleaning both sides of the sheet is preferred.

Very thin substrates (less than 100um) are prone to wrinkling or wrapping the cleaning rollers. This is especially true for film substrates. Polymag® Tek has developed a “Thin Film Transport System” that uses a combination of segmented cleaning rollers and “stripping fingers” that prevent the sheet from wrapping the rollers. See 6RSC-TFSC.

Sheet Cleaners can be driven in multiple ways. We usually drive the bottom cleaning roller. Cleaners can be built with a hand crank, single speed motor or variable speed motor. We can even build the cleaner with a jack shaft for integration into an existing drive mechanism. We can outfit the cleaner with the proper motor and gearbox to meet your needs. Variable speed cleaners tend to cost more because of the addition of controls components like a Variable Frequency Drive.

Machines for use in Europe must be CE compliant. Although our products are built with safety and electrical efficiency in mind, the certification requirements for CE cost around $15,000-$20,000. This is typically much more than the cost of the machine itself. Many of our web cleaning models are CE. The only difference between our web and sheet cleaners in many situations is the drive motor. Hand crank or jack shaft driven units fall under our web cleaner compliance.