Process Roll Cleaners

Contact cleaning technology that removes precipitate and particle buildup from a rotating process roll surface—an efficient cleaning solution that can be customized to a wide variety of manufacturing applications.

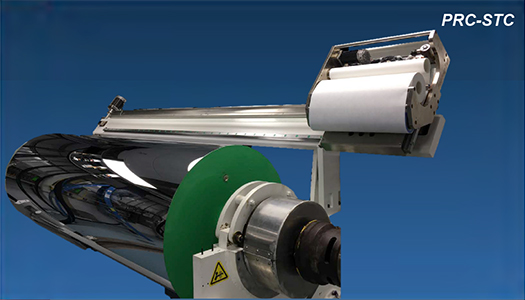

Process Roll Cleaner-Step Traversing

Wide, fabric-covered touch-roll cleaning head performs zonal steps during a quick, traversal cleaning of the rotating process roll surface.

More Details Connect With a Rep

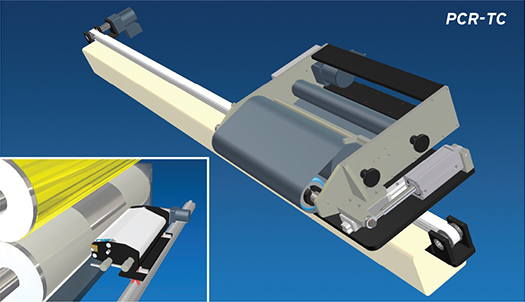

Process Roll Cleaners-Traversing

Wide, fabric-covered touch-roll cleaning head performs a quick, traversal cleaning of the rotating process roll surface.

More Details Connect With a Rep

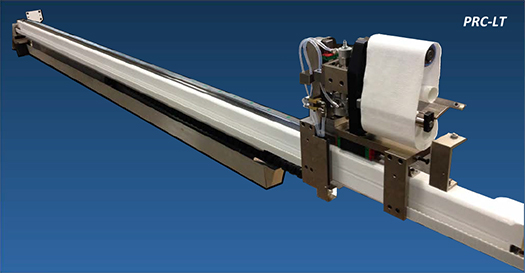

Process Roll Cleaner - Light

An online dry wipe of a process roller in confined spaces where the head engages a soft durometer touch roll, covered with a cleaning fabric, against a driven process roll.

More Details Connect With a Rep

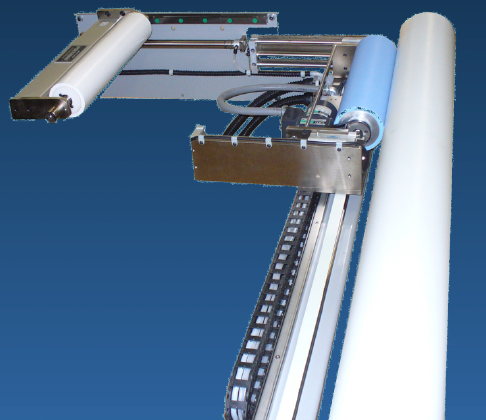

Backing Roll Cleaner

Use a traversing contact cleaning roll to remove contaminants from the backing roll.

More Details Connect With a Rep

Since many systems are unique or limited on space, our design team is highly skilled in making cleaning systems fit your needs.

Frequently Asked Questions

In most cases the roller must be driven. Our cleaning head is pneumatically engaged against the spinning roller and can have a touch force up to 70PSI. High pressure can slow or stop the spinning roller.

Polymag® Tek is proud of our ability to create new designs or modify existing designs in order to fit into tight spaces. Our standard roll cleaning head takes up a profile area of approximately 24” x 16”. We have alternate designs that can reduce that footprint to 12” x 9” or even smaller.

Many roll cleaners are used in a cast extrusion process where the die temperature is well over 400F. Fortunately, the ambient (surrounding) temperature is usually below 120F. If the ambient temperature is above 120F, some of the components on the cleaner need to be specified differently. For instance, the cloth advance motor is replaced with a rotary actuator and all electrical components and sensors are specified for the higher temperature.

The manual process for cleaning a roller usually involves shutting down the line and using a solvent and rags to wipe the roll clean. Because of the frequency of cleaning, a liquid is not usually needed with a roll cleaner. Our mantra is “start clean, stay clean,” meaning that we start with a clean roll, and periodically run a cleaning pass to ensure that the thick buildup that requires liquid to remove never build up.

We do offer a fabric saturation bar that wets the fabric prior to engaging the roll cleaning head. We do not recommend introducing a liquid to your process while you are running because it can alter the roll surface temperature and create streaks or defects in the web/sheet. Wet cleaning can be done as part of a maintenance “deep clean.”

Our mantra is “start clean, stay clean,” meaning that we start with a clean roll, and periodically run a cleaning pass to ensure that the buildup never reaches a level to cause defects. Each process is different and the recipe for frequency of cleaning, roll touch time and number of touches varies per site but is programmable through the HMI.