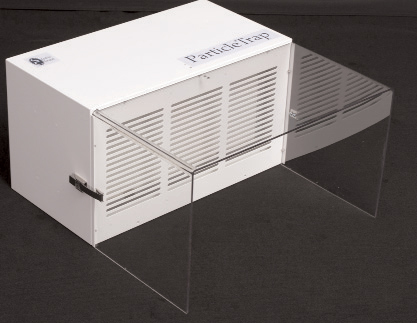

Particle Trap 6000

The Particle Trap 6000 (PT6000) and the Particle Trap Mini (PTM) are source capture systems that solves a major problem when blowing off particles in controlled or clean room environments. With the PT6000 or PTM, you can clean your medical device, optics, packaging materials with confidence while maintaining the integrity of your clean room.

The Particle Trap utilizes a filtration system that includes a Pre-Filter and HEPA Filter combination to trap particulates using negative pressure, permanently removing the contaminants from your environment or clean room. Clean, HEPA filtered air is returned back into the clean room or laboratory, eliminating the need for external duct work and/or the loss of conditioned air in the facility.

When cleaning various substrates, especially plastic parts and packaging trays, compressed air ionizers such as guns, nozzles and airknives are commonly used to neautrilize surface static charge sand blow-off contaminants. While this accepted practice is extremely effective at eliminating electrostatic charges and particles, the question remains...

Where do the particles go?

The problem with conventional “wisdom” is that particles remain in your environment or process,remaining airborne, falling to the floor, onto a workstation or personnel, ultimately finding their way back onto your products or sealed packages. PT6000 or PTM can help increase your yield by reducing costly rejects, tear-downs or rework. By simply blowing-off contaminants from your product or package inside the Particle Trap units, you ensure particulate is trapped inside the systems, where heavier particles fall to the work surface or carry forward into the pre-filter, and finer particles are filtered out by the HEPA filter. The quick change filters make the PT6000 and PTM the ideal system to enhance the process and increase yields that translate into higher profits

Features

- Low-profile, completely portable and affordable, no duct work required

- Compact size, easily positioned on countertops when bench space is at a premium

- Clear viewing through a poly-carbonate hood for optimal visual inspection

- Side clasps allow for easy replacement of the Pre-Filter and HEPA filter

- IIluminating rocker switch visually verifies the system is powered on for customer convenience

- Solid state controller to change fan speed from low to high depending on the application

- Pre-Filter efficiency superior to 95.5% down to 0.5 micron

- HEPA filter designed to capture particles as small as 0.3 microns

- Optional bracket hardware available for wall-mount applications

- Optional floor stands available at the workstation when bench space is limited